The new dimension of metalworking

- Welding & cutting on one system

- Process change < 10 seconds

- 6-axis robotics

- Immediately ready for use via plug & play

- Intuitive operation

CNC welding and cutting system

XFLARE combines the size and precision of a cutting system with the flexibility of a welding robot. From the powerful energy of plasma to the craftsmanship of welding – every cut and every seam combines precision and efficiency on one platform.

XFLARE News

3 Processes on one system!

Ideal for prototypes & small series

Problem:

Small quantities, custom-made products, and the current shortage of skilled workers are pushing many metal fabrication companies to their limits.

Solution:

With XFLARE, metal fabricators can now economically produce small batch sizes up to series production and optimize their processes. The system offers the ideal solution for companies of any size that focus on high utilization and maximum flexibility.

Thanks to its process diversity, the XFLARE replaces multiple machines in a single system and saves valuable production space. The installation of new systems can often be complex and time-consuming, but with the simple plug & play setup, the XFLARE is immediately operational and enables a quick response to customer requirements with its revolutionary operating concept. Additionally, the system ensures greater independence from sheet metal suppliers and welding specialists.

Overview:

- Welding & cutting on one platform

- From prototype to series production

- Revolutionary operating concept

- Intelligent features for high welding & cutting quality

- Cost savings through efficiency

- High flexibility & manufacturing depth

- Quick response to customer requirements

- Contract manufacturing for high utilization

- Personnel savings through automation

- Independence from sheet metal suppliers

– Stephan Günthner, Günthner Metallbau

Lightning-fast process change

Say goodbye to time-consuming reconfigurations and maximize your productivity with XFLARE. The innovative tool change system enables a quick process change in < 10 seconds! Seamless operation is ensured through automatic process recognition.

Learn more about the process features

The combination of welding and cutting system offers maximum flexibility for various requirements, with minimal rework and without loss of quality. It combines multiple processes in one system, saves both space and costs, and can be quickly adapted to your current order situation.

100%

Automated processes ensure consistent performance and reproducible results – independent of operator or shift. Using a laser distance sensor, components are precisely detected to ensure the highest manufacturing standards.

- Revolutionary operating concept

- Automatic component detection

- Qualifiable processes

- Consistent results

Welding robot with 6-axis kinematics

Experience state-of-the-art process equipment and exceptional flexibility!

Metal construction

Steel industry

Shipbuilding

& many more

Diverse application areas!

Material, angle, shape, size …

With the intelligent 6-axis robotics of the XFLARE, any desired shapes can be manufactured from the raw material. It enables diverse processing options for sheets, beams, pipes, vessel bottoms, and welding assemblies, for both precise 2D and 3D processing. All sides and angles of the component are effortlessly and precisely reached.

From cutting holes, contours, bevels to probing and marking to demanding welding tasks – the XFLARE masters every task with excellence.

Efficient

The high portal allows processing of large components such as dished heads, beams, or complex welding assemblies. Integrated conveyor rollers facilitate the transport of heavy sheets. The smart drawer system allows comfortable disposal of the output!

- High portal for large components

- Easy accessibility

- Movable drawers

- Height-adjustable conveyor rollers

- Integrated underfloor extraction

Large working area – many possibilities

The XFLARE is available in two sizes and impresses with highest efficiency and minimal space requirements in both small and large formats. The spacious working area and a high portal also allow processing of large components, while all necessary processing points can be easily reached.

XFLARE S-1

Dimensions:

3,500 x 2,000 x 2,800 mm

Construction space:

2,000 x 1,000 mm

Portal clearance:

approx. 560 mm

Weight:

1,600 kg

Permissible area load:

max. 2,000 kg

Permissible point load:

max. 500 kg

XFLARE L-1

Dimensions:

4,500 x 2,400 x 2,800 mm

Construction space:

3,000 x 1,500 mm

Portal clearance:

approx. 560 mm

Weight:

max. 500 kg

Permissible area load:

max. 3,000 kg

Permissible point load:

max. 1,000 kg

Would you like to learn more?

Request the technical specifications through our data sheet!

Qualifiable processes according to ISO

Our welding and cutting systems can meet the stringent requirements of ISO standards DIN EN 1090, DIN EN 15085, and DIN EN 15614, among others. This ensures consistently high quality in every production step and ensures that our processes are not only efficient and safe but also operate with the highest precision and reliability.

Contact us for your specific application.

Discover the numerous XFLARE features

The welding and cutting system combines flexibility with robustness. High-quality components and intelligent solutions are incorporated into every detail to increase operational time and lifespan, as well as ensure safe operation. Conceived by experienced experts, the system was created to pave the way for effortless and sustainable top quality.

Control panel

27" display – 350° swivel

Conveyor rollers

Height adjustable

Handwheel

With magnetic mount

Drawers

Efficient material removal

Accessory compartment

Storage of equipment

Control cabinet

Integrated into the system

Energy chain

All cables neatly stowed away

Tooldock

For 2 tools simultaneously

XFLARE Portal

Display of operating states

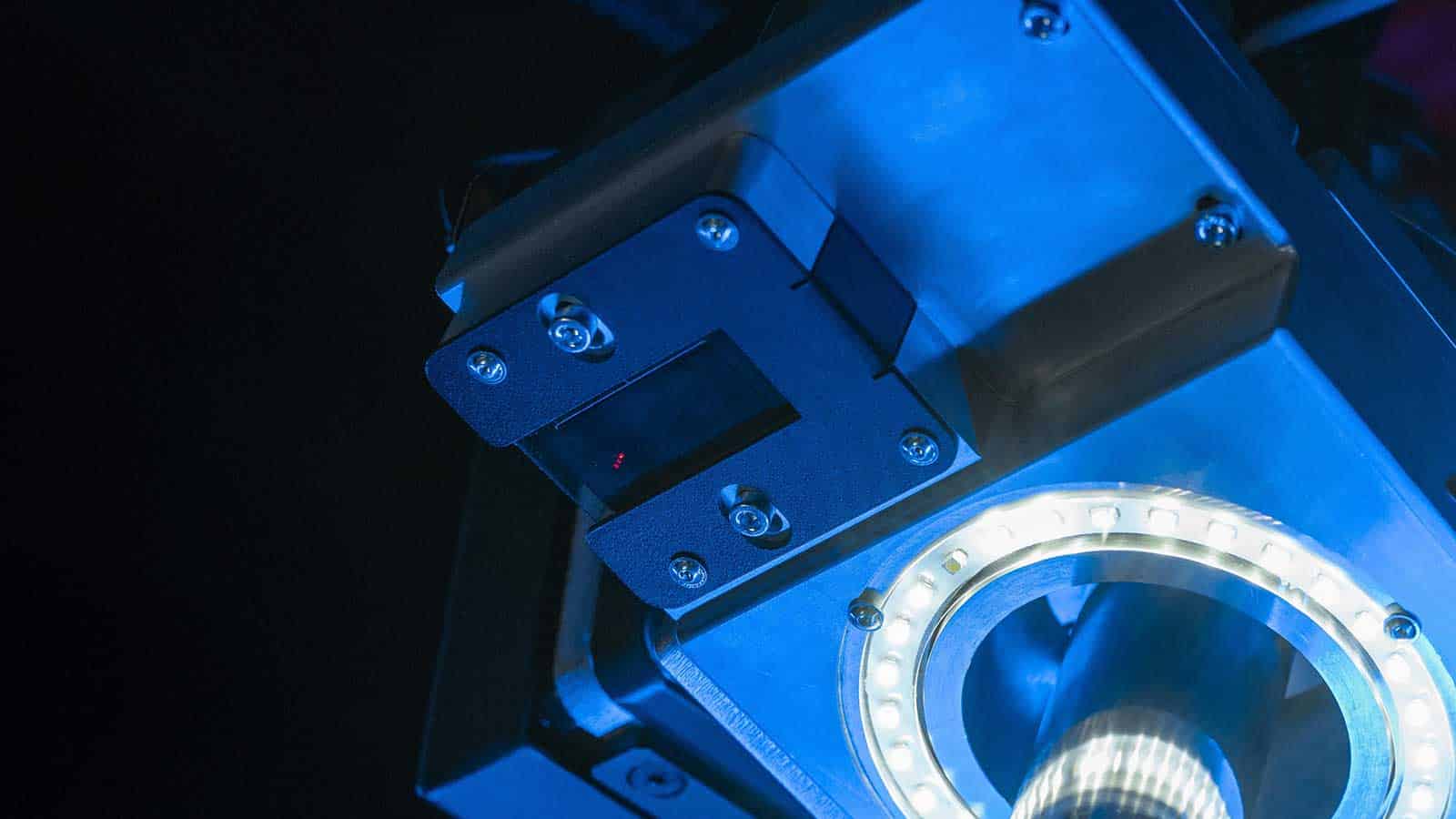

Tool head

6-axis machining

Extraction

Is switched on sectionally

Extensions for the XFLARE

XFLARE can be expanded with various system options that optimize your manufacturing processes.

Set up

Thanks to quick commissioning via plug play, the XFLARE is immediately ready for use. The instruction takes only a few hours, allowing you to start your welding and cutting work without delay.

- Plug play: only electricity, compressed air process-dependent gases

- All-in-one package

- Easy operation

- No programming required

Revolutionary operating concept

With XFLARE, welding and cutting become effortless. The XFLARE software is optimally tailored to the processes and controllable via an intuitive user interface that is easy to operate even without programming knowledge. With intelligent functions, solutions can be quickly created and reproduced in series, minimizing dependence on operator expertise and typically reducing training time to just a few hours.

A rotatable control panel provides full overview, especially in teach mode, while quickly accessible parameters and tools minimize downtime and maximize operating time.

Overview:

- Easy operation

- Minimal training effort

- Simple program creation

- Combined offline programming teaching

- Fully integrated workstation

In steps to your XFLARE!

Free consultation

Would you like to see XFLARE in action and experience its benefits live? Book a demonstration now and get a consultation.

Customized offer

Did you like what you saw? We’d be happy to provide you with a customized offer immediately.

Short delivery time

Thanks to our fast production and always available inventory, you’ll receive your XFLARE within 4 weeks.

Easy installation

The compact system is delivered in one piece and installed within minutes via plug play.

Quick commissioning

The simple operation allows for quick commissioning and minimal downtime.

The XFLARE in action

Experience the XFLARE in action: from tool changes to circumferential and fillet welding to probing and cutting beams — the XFLARE shows how easy combined processes can be.

Innovative machines from Neu-Ulm

The XFLARE was developed and manufactured by XTRACTION. The company, based in Neu-Ulm, Bavaria, pursues the highest standards in quality, aesthetics, and functionality of its products. Our unique service accompanies you from the idea to delivery and beyond, including assembly, maintenance, and after-sales service. Here you receive premium quality and competent service directly from the manufacturer.

Service directly from the manufacturer

From conception to installation, we offer a comprehensive service under one roof. The fully internally developed software is continuously tested and further developed to maximize machine uptime and efficiency and ensure smooth operation. In addition, we offer individual training and maintenance services.

Replacement wear

Easily accessible lubrication points and easily replaceable wear parts simplify maintenance.

Maintenance

For smooth operation, we’re happy to take care of regular maintenance. Simply send us an inquiry.

Training

In an individual training session, you’ll learn how to optimally handle the machine. Interested in training?

This means less rework thanks to highest precision and dimensional accuracy. This is also reflected in the specially developed guide rail, the robust portal bridge with double guidance, and the high-quality components that guarantee long-term use.

- Robust construction

- Long service life

- High value

- Low maintenance

- Comprehensive safety standards

Experience XFLARE live!

Participate in an exclusive presentation where a qualified XFLARE technician demonstrates the comprehensive functionality of the machine. You have the opportunity to test the system live and see how it meets your requirements. You are welcome to provide your own drawings and materials for samples.